| |

|

|

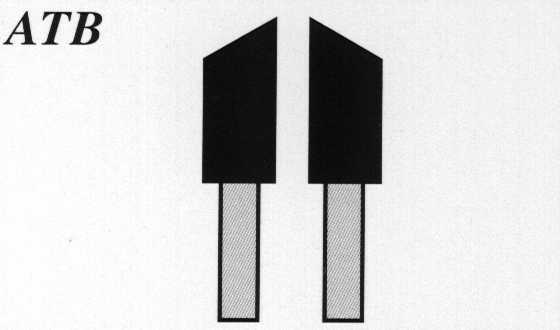

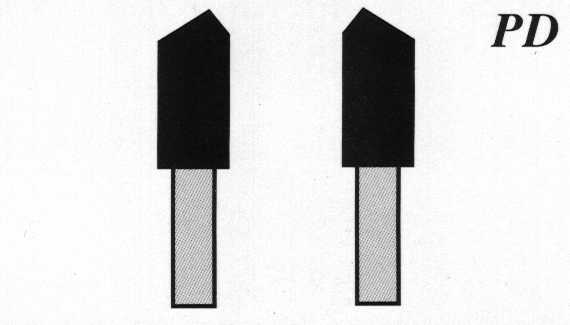

Alternate Top Bevel Grind

excellent for cutting operations with and/or against the grain. Achieves a

fairly high level of quality over a wide range of cuts. Two sets of shearing

action alternate left and right, top bevel teeth facilitate chip removal. To cut

very thick material, choose a lesser number of saw teeth. |

|

|

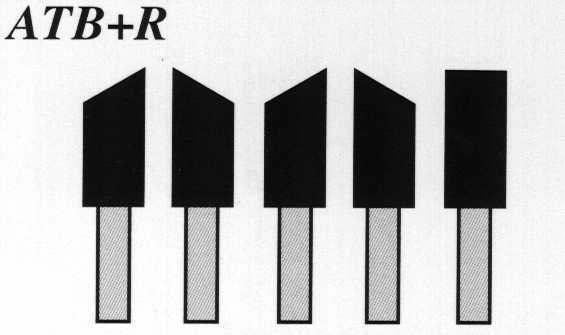

Alternate Top Bevel Grind and Raker

For across the grain cutting and/or cutoff and trimming operations on

undefined grain material. Top bevel shaped teeth sever the material with

shearing action alternating right and left followed by a raking action flat top

tooth with large round gullet to facilitate chip removal. Given a choice, the

ATB+R sawblade with the higher number of teeth will produce the higher quality

of finished cut. |

|

|

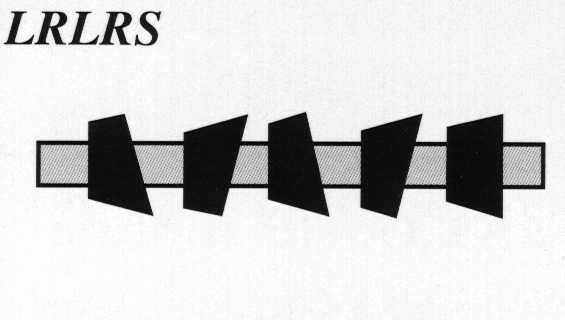

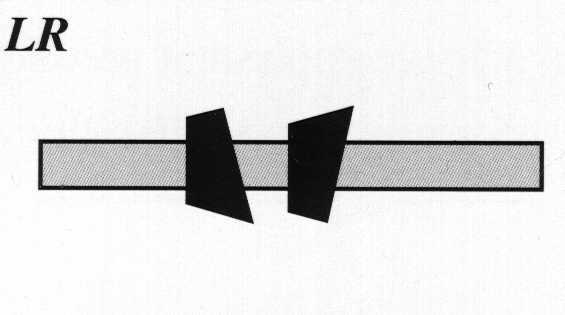

Left Right Left Right Straight with Face Bevel

Tooth design is like the ATB+R above, but in 5 teeth groupings with the

teeth all having a face bevel on the first two sets and a straight face on the

fifth tooth. Specially designed for a very smooth cutting finish required on

solid wood or composition material. |

|

|

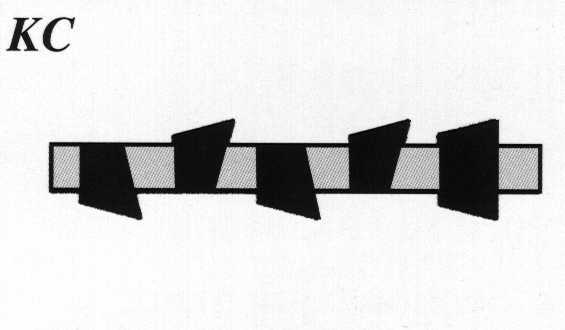

Single Side Left Right Left Right Straight with

Face Bevel

This design is similar to the LRLRS tooth design, except that the teeth are

confined to a singular side. By not overlapping the sawblade body the sawdust

has an easier path of escape and the cutting takes less effort. |

|

|

Left Right with Face Bevel

Tooth design is like ATB tooth design above, but in two teeth groupings with

alternating beveled tops and faces. |

|

|

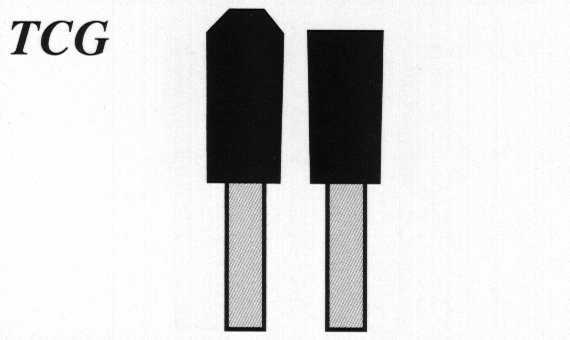

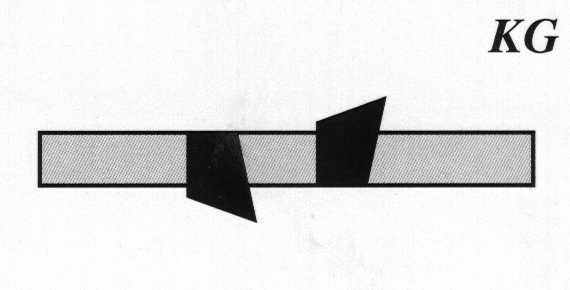

Triple Chip & Flat Grind

Two shapes of teeth-alternate triple-edge and flat top design for dual

action cutting. Triple-edge teeth chip down the center of the kerf; flat top

raker teeth follow to clean out material from booth sides. TCG sawblades with a

negative hook angle are recommended for cutting non-ferrous metals. Negative

hook angle prevents climbing, giving you total control over the feed rate. |

|

|

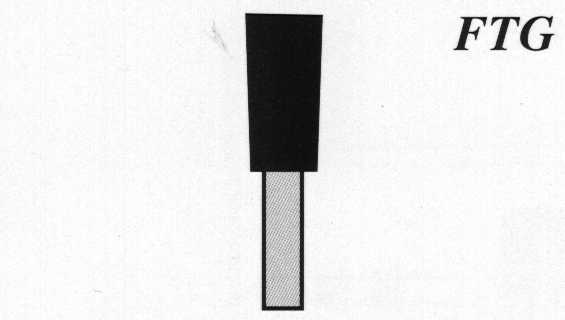

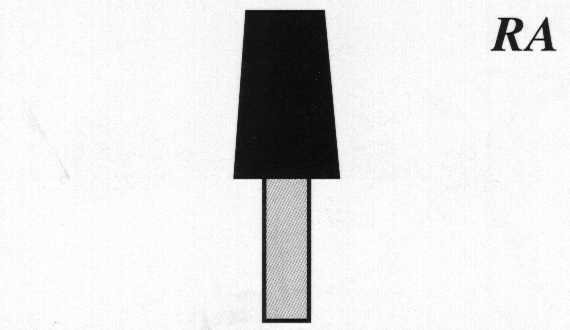

Flat Top Grind

Generally, for cutting material with grain. Larger gullets on this type of

sawblade accept greater chip loads; permit higher feed rates. Excellent for

ripping on either single or multi-rip machines where speed of cut is more

important than quality of cut. Teeth with flat top shape act as chisels, cutting

material with chisel like action. Also serve as rakers to clean out the cuttings

or chips. |

|

|

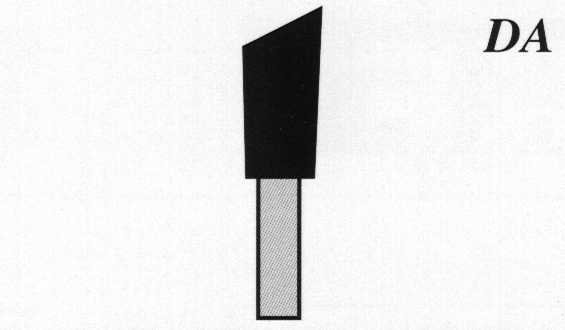

All Right Hand Direction with Top Bevel

This tooth design with have Right-Hand Top Bevels. All of the teeth will be

beveled in the same right-hand direction. This design of beveling will produce a

very fine cutting edge. The tooth design is best used for pre-sawing, scoring,

and tenoning. |

|

|

All Right Hand Direction with Top Bevel

This tooth design will have Right-Hand Top Bevels. All of the teeth will be

beveled in the same right-hand direction. This design of beveling will produce a

very fine cutting edge. The tooth design is best used for pre-sawing, Scoring,

and tenoning. |

|

|

Flat Top with Tapered Side

these teeth will have flat tops and tapered sides. This design is for

sawblades used for scoring prior to cutting boards. |

|

|

Single Side Left right with face Bevel

This design is similar to the LR tooth design, except that the teeth are

confined to a singular side. By not overlapping the sawblade body, the sawdust

has an easier path of escape and the cutting takes less effort. |

|

|

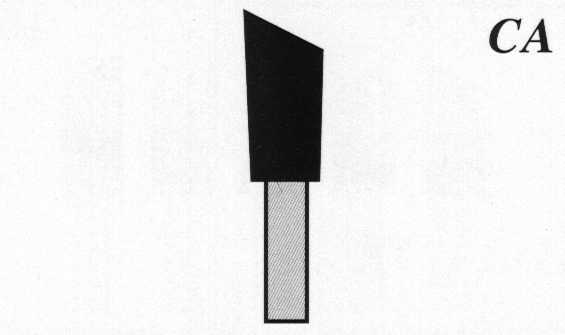

Alternate Top Bevel with Chamfer

This design consists of a beveled top with 1/3 45 degree chamfer. |

| |

| |